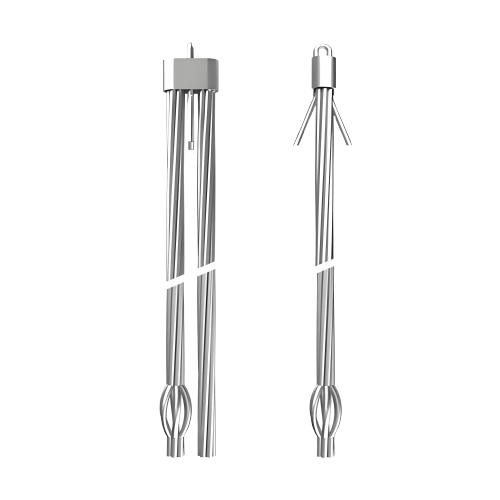

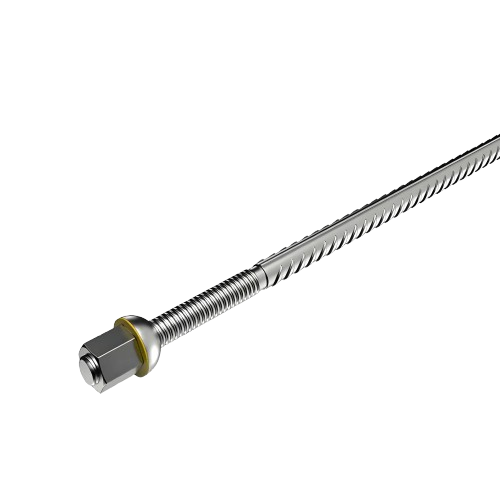

Fiberglass Rebar

Glass fiber reinforced polymer (GFRP) bolt is formed by high strength glass fiber and resin curing agent through high temperature curing.

The whole length of the bolt is thread type, the thread direction is left or right rotation, and the thread distance is generally 10mm round head thread.

After the fiberglass bolt is driven into the rock, under the action of anchoring agent, the fiberglass bolt body is bonded to the surrounding rock mass. Under the interaction between the fiberglass bolt and the surrounding rock mass, the stress state of the surrounding rock is changed, the overall stiffness of the rock mass is improved, and the deformation resistance and bearing capacity of the rock mass are enhanced.

This revolutionary material is engineered to withstand the challenges posed by corrosive environments, a persistent issue with steel reinforcement. Fiberglass rebar is inherently corrosion-resistant, making it an ideal choice for projects in coastal areas, chemical processing plants, or any environment where exposure to harsh elements is a concern. Its non-corrosive nature not only extends the lifespan of reinforced structures but also reduces maintenance costs over time.

Product Features

-

Lightweight

-

High Strength

-

Corrosion Resistance

-

Electrical Insulation

Product Parameters

| Diameter

(mm) |

Length

(m) |

Cross Section

(KN) |

Tensile Strength

(KN) |

Tensile

Modulus |

| 16 | 0.6 - 3 | 185 | 125 | 40 |

| 18 | 0.6 - 3 | 234 | 160 | 40 |

| 20 | 0.6 - 3 | 289 | 200 | 40 |

| 22 | 0.6 - 3 | 355 | 220 | 40 |

| 25 | 0.6 - 3 | 442 | 320 | 40 |

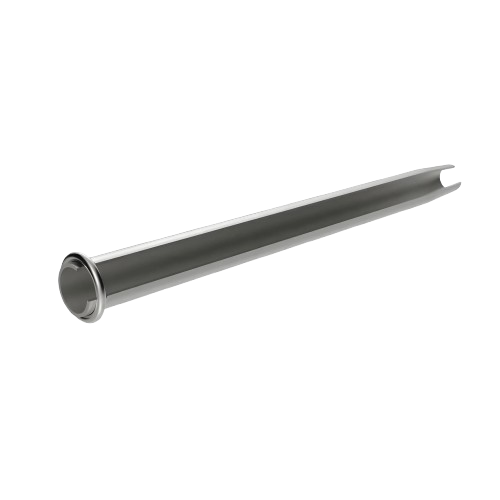

· Color: Default color is black

· Other colors are optional (consult the salesperson)