Underground coal mining remains one of the world's most vital yet challenging industries, providing a crucial energy resource under increasingly complex geological conditions. The single most critical factor in ensuring the safety of personnel and the efficiency of operations is the integrity of the underground support system. In the demanding environment of a coal mine, where high stresses, weak strata, and dynamic loads are commonplace, conventional support methods often prove inadequate. ZHONGFU, a leader in the design and manufacturing of high-performance ground support products, is dedicated to providing specialized, reliable, and innovative solutions that meet the rigorous demands of modern underground coal mining.

The Unique Challenges of Coal Mine Roadway Support

The geology of coal seams presents distinct challenges that differentiate it from other tunneling or civil engineering projects. Coal measure strata are often characterized by their softness, layered nature, and susceptibility to deformation. Key challenges include:

• High Horizontal Stresses: Resulting from tectonic activity, leading to severe floor heave, roof sag, and rib deformation.

• Weak Immediate Roof and Floor: Typically consisting of soft shale, mudstone, or sandstone that can deteriorate quickly when exposed to air and moisture.

• Dynamic Loading: The sudden release of energy during roof falls or coal outbursts poses a significant risk to both equipment and personnel.

• Large Cross-Sectional Roadways: Modern mines require wider and higher roadways for equipment passage and ventilation, increasing the span of unsupported ground.

• Long-Term Durability: Support systems must maintain their load-bearing capacity over the entire lifecycle of the mine.

A failure to adequately address these issues can lead to catastrophic consequences, including collapse, entrapment, and production stoppages. ZHONGFU’s comprehensive support systems are engineered specifically to counteract these forces and create a safe working environment.

The ZHONGFU Support System: A Multi-Faceted Approach to Mine Stability

Our philosophy is based on creating a synergistic support system where each component works in concert to reinforce the rock mass, control deformation, and absorb energy.

1. High-Tensile Rock Bolts and Cable Bolts:

The backbone of any modern coal mine support system, ZHONGFU’s rock bolts are designed for rapid installation and high load-bearing capacity. We offer a range of solutions tailored to different conditions:

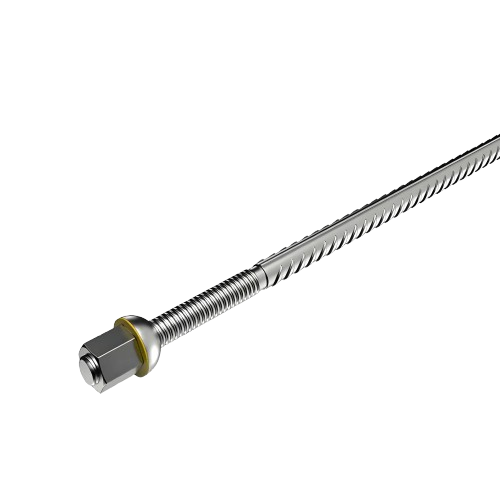

• Full-Column Resin-Grouted Rebar Bolts: These provide excellent bonding with the rock mass, creating a thick, reinforced zone in the immediate roof. Our high-yield steel rebar offers superior tensile and shear strength.

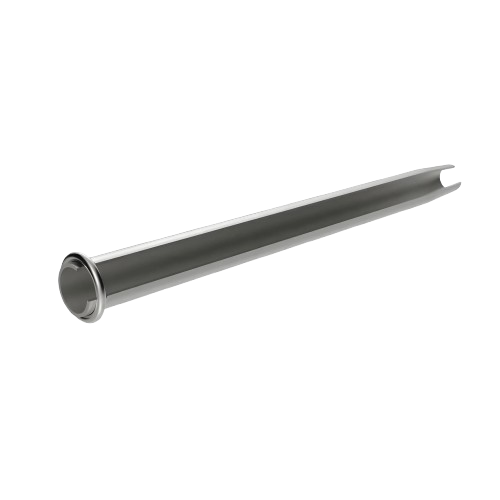

• Friction Rock Stabilizers (Split Sets): For providing immediate support in medium-stress conditions, these are ideal for securing the rib sides and stabilizing broken ground.

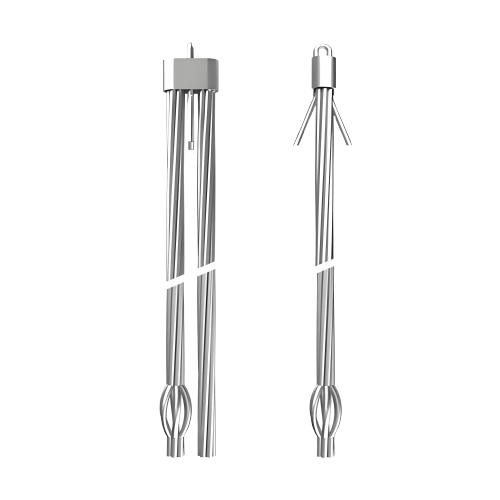

• High-Capacity Cable Bolts: For longwall tailgates, main gate roads, and areas under very high stress, our multi-strand cable bolts offer the extended reach and high load capacity needed to anchor deep into stable strata beyond the fractured zone.

2. Steel Arches and Lattice Girders for Heavy-Duty Support:

In areas with extremely weak ground or high deformation pressures, such as main haulageways or shaft stations, ZHONGFU’s heavy-duty steel sets (arches) and lattice girders provide the necessary rigid, continuous support. Their high yield strength allows them to withstand enormous pressures while maintaining the roadway profile, ensuring safe access for personnel and equipment.

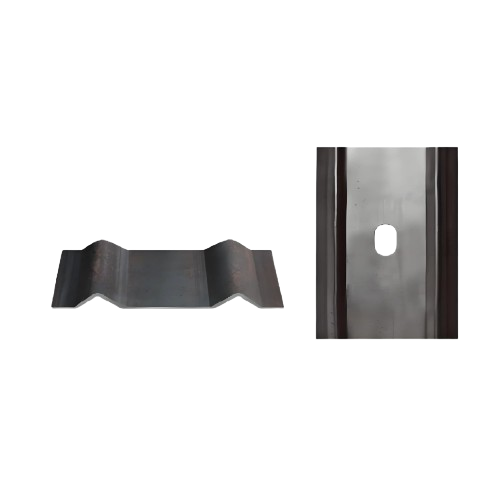

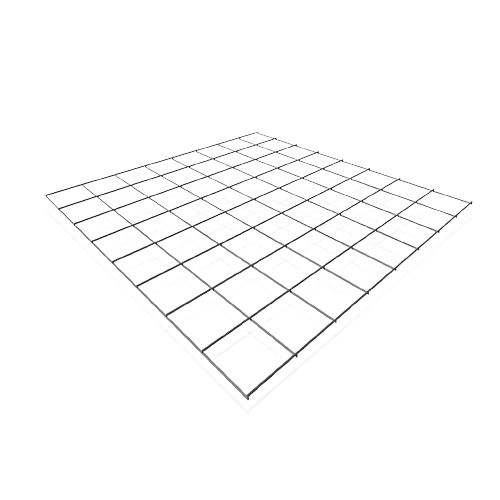

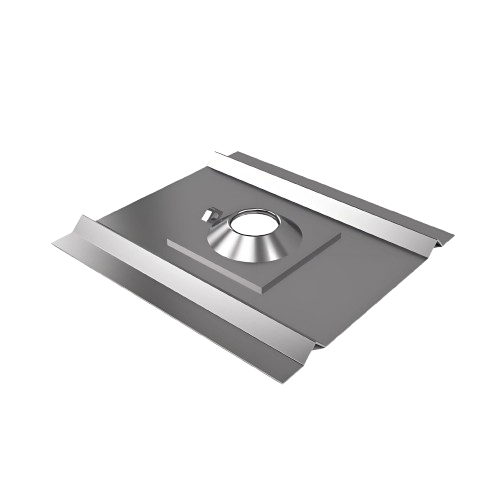

3. Weld Mesh and Straps for Surface Control:

To prevent loose rock from falling between bolts and to contain the broken rock mass, surface restraint is essential. ZHONGFU manufactures high-tensile weld mesh and steel straps that work seamlessly with our bolt systems. These components bind the bolted zone together, distribute loads more evenly across multiple bolts, and provide a secure surface for shotcrete application if required.

4. Shotcrete and Pumpable Sprays for Sealing and Reinforcement:

Shotcrete plays a dual role in coal mine support. As a primary layer, it seals the exposed rock surface, preventing weathering and disintegration of weak strata. As a secondary layer, it integrates with the bolt and mesh system to form a solid, structural shell that significantly increases the overall stiffness and load-bearing capacity of the support system. Our specialized accelerator admixtures ensure rapid setting, even in wet conditions.

Application in Critical Mining Scenarios

ZHONGFU’s products are deployed across the entire mining cycle:

• Longwall Panel Development: Securing gate roads against the intense abutment pressures from the advancing longwall face.

• Pillarless Mining (Yielding Pillar Systems): Providing yield and abutment cable bolt support that allows for controlled deformation while maintaining roadway stability.

• Mine Outages and Rehabilitation: Offering robust solutions for repairing and re-supporting damaged roadways, ensuring their return to safe, operational condition.

• Seam Development Drivages: Ensuring stable and safe roadways during the initial development of the mine.

The ZHONGFU Commitment: Partnership for a Safer Mine

Choosing ZHONGFU is a strategic decision for any mining operation focused on safety and productivity.

• Technical Expertise: Our engineers understand the unique geomechanics of coal mines. We provide support design recommendations and on-site technical assistance to optimize your ground control plan.

• Quality and Reliability: In an industry where failure is not an option, every ZHONGFU product is manufactured to the highest quality standards, undergoing rigorous testing to ensure consistent performance.

• Innovation for the Future: We continuously invest in R&D to develop next-generation support solutions, including yielding bolts for high-deformation zones and smart bolts with integrated monitoring capabilities.

Conclusion

The relentless pressures of the deep earth demand an equally resilient response. In the high-stakes environment of underground coal mining, the margin for error is zero. ZHONGFU stands as a trusted global partner, providing the advanced engineering, superior products, and unwavering commitment necessary to protect your most valuable assets: your people and your productivity. By integrating ZHONGFU’s comprehensive support systems, mining operations can navigate complex geological challenges with confidence, ensuring not just the extraction of coal, but the guaranteed safety of all those who work below.

Build a safer, more productive mine from the ground up. Partner with ZHONGFU.